bauxite processing into aluminum

ترك تعليقك

The Manufacturing Basics of Aluminium

MANUFACTURING PROCESS. 1. Bauxite Mining. Bauxite is used as the main raw material in the manufacture of aluminium. It is a clay mineral found in tropical and subtropical areas such as Australia and the West Indies. The bauxite is often mined from only a few metres below the ground level. About 45 tonnes of bauxites are required for 1 tonne ...

Bauxite and Alumina Statistics and Information | ...

Bauxite is a naturally occurring, heterogeneous material composed primarily of one or more aluminum hydroxide minerals, plus various mixtures of silica, iron oxide, titania, aluminosilie, and other impurities in minor or trace amounts. The principal aluminum hydroxide minerals found in varying proportions with bauxites are gibbsite and the ...

Australia's Bauxite and Alumina Industries

Mar 14, 2022 · Australian bauxite and alumina will help meet global demand for aluminium. Australia is the world's largest producer of bauxite, mining more than 100Mtof bauxite a year, or about a quarter, of global production. About 40% of this is exported and 60% is turned into alumina here in Australia. We are the world's

aluminum processing | History, Mining, Refining, Facts ...

aluminum processing, preparation of the ore for use in various products. Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of grams per cubic cm. The most abundant metallic element, it constitutes percent of Earth's crust. In nature it occurs chemically combined with oxygen and other elements.

Aluminium

Bauxite is the basic raw material that is refined into alumina, which in turn is sent to smelters for processing into aluminium. First discovered near Les Beaux in the South of France in 1821, bauxite was initially called "beauxite". In 1886, Charles Martin Hall and Paul Héroult independently developed a process for making aluminium from ...

The aluminium production process | Comhan Aluminium

The complete production process from aluminium is a fascinating procedure. Starting with the extraction of the bauxite, through to the conversion of alumina and ultimately to the entire electrolysis process. The end product: pure aluminium, ready to be further processed by postprocessing companies.

Bauxite: The principal ore of aluminum.

Bauxite Used for Aluminum Production. Bauxite is the principal ore of aluminum. The first step in producing aluminum is to crush the bauxite and purify it using the Bayer Process. In the Bayer Process, the bauxite is washed in a hot solution of sodium hydroxide, which leaches aluminum from the bauxite.

Aluminum Smelting and Refining

Both primary and secondary aluminum producers refine and melt the aluminum and pour it into bars called ingots. The ingots are shipped to metal casting plants or other shaping plants for molding or rolling. Primary Aluminum Refining. Aluminum production .

Noranda Jamaica rebranding to Discovery Bauxite, US ...

Nov 14, 2021 · Noranda said the name Discovery Bauxite is both a tribute to its home base in Discovery Bay, as well as to the discovery process that is fundamental to alumina and aluminium. "The rebranding is an opportunity for us to usher in a new chapter for our business in more ways than just the name," New Day said without elaborating on future plans.

Handling of bauxite

Bauxite is one of the world s most abundant minerals and is stripmined in many places. Nearly all is processed into alumina for aluminium production. Bauxite contains ironbearing clay or red mud, which often leaves stains on the hold paint that can prove difficult to remove. Bauxite is an aluminium ore and is the main source of aluminium.

What Is the Bayer Process? (with picture)

Feb 11, 2022 · Sanker Date: February 11, 2022 The Bayer process is an industrial process by which bauxite is purified into alumina, or aluminum oxide.. The Bayer process is an industrial process by which bauxite is purified into alumina, or aluminum oxide. Named for Karl Bayer, who developed it in the late 19 th century, this process is an essential intermediate .

Bauxite the ore of aluminium is purified by which process ...

Therefore, the Hall's process used to purify the bauxite ore. The answer is option B Additional Information: About 70 percent of the world's bauxite produced is refined through the bayer chemical process into alumina. Alumina is then refined into the pure aluminium metal through the HallHeroult electrolytic process.

From Bauxite to Alumina to Aluminum

Check bauxite for available alumina and impurities to minimize the use of reagents and energy in downstream processing. Save energy costs by fast and accura...

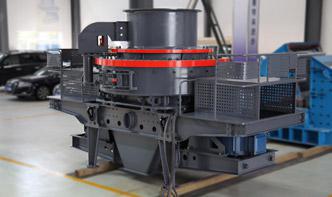

Bauxite Grinding And Classifiion Type Of Screen Portable

Bauxite Processing Plant Bauxite Ore Crushing And Ore ... Of Bauxite Into Alumina's Grinding Mill,Bauxite Bauxite Grinding Mill Used In Alumina. do not dissolve in water, can be dissolved in molten cryolite, is the main raw material for aluminum production. ... function the jobholder contributes to ...

TENORM: Bauxite and Alumina Production Wastes

Oct 06, 2021 · The Bayer Process, which is used by about 80 active plants worldwide, is the primary method of producing aluminum from bauxite. Bauxite ore is dissolved in sodium hydroxide, or lye, at a high temperature and pressure. Then, the alumina and bauxite ores are separated by washing out the waste (red muds or sands) from the alumina.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك