process of ore separated from platinum

ترك تعليقك

Sat How To Separate Platinum From Iron Ore Search By

how to separate platinum from iron ore search by search titles only posted by member separate names with a than i have found silver,gold,copper,and even platinum but no iron ore Iron oxide copper gold ore deposits Wikipedia Iron oxide copper gold ore deposits Jump to navigation Jump to search. How To Separate Platinum From Iron Ore Search By. Iron ore Wikipedia. Iron ore .

How To Separate Platinum From Iron Ore Search By

How To Separate Platinum From Iron Ore Search By. Iron ore Wikipedia. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. Indeed, it has been argued that iron ore is "more integral to the global economy than any other commodity, except ...

RECYCLING OF PLATINUM GROUP METALS FROM AUTOMOTIVE ...

Platinum 2012 695 R. Rumpold, J. Antrekowitsch RECYCLING OF PLATINUM GROUP METALS FROM AUTOMOTIVE CATALYSTS BY AN ACIDIC LEACHING PROCESS R. Rumpold University of Leoben J. Antrekowitsch University of Leoben Abstract The platinum group metals (PGMs) palladium, platinum, and rhodium represent the key materials for .

Sat How To Separate Platinum From Iron Ore Search By

Sat How To Separate Platinum From Iron Ore Search By . Mega Scan Pro 2020 metal detector can be used as a multipurpose device because it is including three search systems within a single device, providing the possibility to detect all kinds of precious metals such as silver, copper, bronze and platinum, buried gold treasures, raw natural gold ore and underground .

Learn About Rhodium, a Rare Platinum Group Metal

· Wollaston dissolved platinum ore in aqua regia (a mixture of nitric and hydrochloric acids) before adding ammonium chloride and iron to obtain palladium. He then found that rhodium could be drawn from the chloride salts that remained. Wollaston applied aqua regia then a reduction process with hydrogen gas to obtain rhodium metal. The remaining metal showed a .

The Properties and Appliions of Platinum

· Extracting platinum from ore is both capital and laborintensive. It can take up to 6 months and 7 to 12 tons of ore to produce one troy ounce () of pure platinum. The first step in this process is to crush platinum containing ore and immerse it in the reagent containing water; a process known as 'froth flotation'. During flotation, air is pumped through the ore .

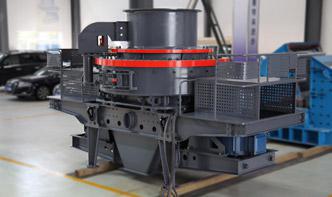

Dense Media Separation (DMS) Plants

· The heavy medium beneficiation process includes ore preparation, ... Heavy medium vibration chute uses heavy flotation liquid to separate coarse ore (hematite, manganese ore, and other ferrous metals) in the vibration process, feed ore size is generally 756mm. 【Working Principle】 Under the action of chute shaking and rising water flow, the heavy .

Recovery and Then Individual Separation of Platinum ...

· Recovery of PGMs (especially rhodium, platinum, and palladium) from different spent manufactured products (like alytic converters) is considered as an important task as they are rarely found in nature, and they possess high economic value. In this work, the honeycomb of a car alytic converter was primarily processed by crushing, grinding, and then treating in a .

Platinum (Pt)

Platinum nuggets occur naturally as the uncombined metal, as does an alloy of platinumiridium. Threequarters of the world's platinum comes from South Africa, where it occurs as cooperite, while Russia is the second largest produced, followed by North America. World production of platinum is around 155 tonnes a year and reserves total more than tonnes

(PDF) Platinum smelting in South Africa

Using this process, copper, lead, and PGE associated with oxide minerals get separated (Freeman, Newell and Quast 2000; Jones 1999; Kongolo et al. 2003). The ROM sample of Nkomati −75 µ size ...

Process Description and Abbreviated History of Anglo ...

The Anglo Platinum Process Route Ore from mining operations reaches the various concentrators at a platinum head grade of ~3 g/t, while metallics are sent directly to the Precious Metals Refinery (PMR). The ores undergo crushing, milling, and separation by sulphide flotation, to concentrate the base metals sulphides and the associated platinum group metal (PGM) .

platinum ore refining process

Platinum Mining and Refining Eduion. 28/01/2018 Refining platinum ore is a costly and laborious process. It can take from eight weeks to six months to process a batch of ore, and it can take up to 12 tons (11 tonnes) of ore to produce a single troy ounce of platinum.

platinum group | chemical element group | Britannica

platinum group, six metals, in order of increasing atomic weight, ruthenium (Ru), rhodium (Rh), palladium (Pd), osmium (Os), iridium (Ir), and platinum (Pt). The elements all possess a silvery white colour—except osmium, which is bluish white. The chemical behaviour of these metals is paradoxical in that they are highly resistant to attack by most chemical reagents yet, employed .

Extraction of Platinum Group Metals | IntechOpen

· PGM ore smelting. To separate the PGMrich sulphides from the gangue minerals, smelting is used. Rectangular sixinline or circular threeelectrode electric furnaces are typical in the PGM industry . Smelting is a hightemperature process step where the sulphides (valuable minerals) are separated from the silies (gangue minerals). Energy required for melting the .

Distillation: It's a Gas .Separation ...

· Interestingly, the reverse process can be used to separate gases by cooling the gas until the individual gas components condensate into a liquid. Distillation is used to collect and purify many chemicals, such as alcohol, gasoline, distilled water, xylene, paraffin, kerosene, and many others. The simple distillation process described above can only be used to separate .

process of ore separated from platinu

2016 2 21ensp·enspThe first process: The impurities are removed in the first part of the process, when de gangue is separated from the ore. 5. The second process of preparing the mineral of iron is: The mineral is washed to remove dirt. It´s crushed into sand. The sand is sieved, and then, again separated from the ore . Contact Me

The Biggest Platinum Metal Producers

· Vale SA is the world's secondlargest mining company, the leading producer of iron ore and pellets and the world's secondbiggest nickel producer. It also produces 134,000 ounces of platinum annually. As many nickel ores also contain PGMs, Vale is able to extract platinum as a byproduct of its nickelrefining process. The company takes PGM ...

The Improvement of Platinum Recovery Ratio in the ...

recovering platinum by depositing the ore in a molten salt ... The dissolution process of platinum using dry aqua regia was the same in the previous ) A mixture of equimolar iron chloride (III) and potassium chloride was used as the dry aqua regia and adjusted to achieve a weight of 3g. Then, this adjusted mixture along with a platinum wire sample of .

Separation of platinum, palladium and rhodium from aqueous ...

· Impala Platinum process (Adopted from Crundwell et al. ). This was developed specifically to process PGM sulfide concentrates [62], [80], [204] . The leaching of the concentrates was carried out with oxygen in sulfuricchloride media under conditions of 220 °C, 700 kPa O 2 and 3200 kPa total pressure, resulted in total recovery of base metals, Pt and Pd, .

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك