gold milling process in oman

ترك تعليقك

Operating Costs of Gold Processing Plant

· The EXAMPLE Gold Mill is designed to process 500 tonnes per day of ore. The flowsheets are conventional and consist of two stages of crushing, single stage ball mill grinding, cyanidation and a MerrillCrowe precipitation circuit for gold and silver recovery. In addition to the cyanide circuit, gold leach residue is treated in a flotation stage to recover unleached silver .

Al Hadeetha CopperGold Project, Sultanate of Oman

Credit: Alara Resources Limited. Loed in the Sultanate of Oman, Al Hadeetha is a highgrade coppergold project. Al Hadeetha Resources (AHR) joint venture (JV) between Alara Resources subsidiary Alara Oman Operations, Al Hadeetha Investments and Al Tasnim Infrastructure Services is developing the project. AHR became the first JV to secure a ...

How gold is extracted by Cyanidation Process

· The process of extracting gold by cyanidation process involves three important steps that have to be looked into: The first step involves bringing the finely ground ore and the cyanide solution, Then removing the solids from the clear solution, and ; Lastly recovering precious metals from the clear solution by a method known as the precipitation of zinc dust. .

Alara Resources plans coppergold plant in Oman

· Alara Resources ... to conduct feasibility study for 800,000 tpa capacity coppergold processing plant Alara Resources plans coppergold plant in Oman

What Is Toll Processing | Custom Milling Consulting LLC

Toll processing is also commonly referred to as contract processing, tolling, toll milling, toll conversion, toll manufacturing, or custom manufacturing. It is a process that can be defined as performing a specific service on the product of a client. Naturally, the company would charge a fee (more commonly referred to as a toll) to perform these services. Generally, a company would .

Mine onestop service

Rod Mill. Flotation cell. Linear Vibrating Screen. Thickeners Mining. Solutions . Gold Cyanide Process. Gold Cyanide Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%. more .

Gold processing technology for viable mining

We have developed Rapid Oxidative Leach (ROL), a pretreatment process that has already generated interesting results in the copper industry and now has its own development track for refractory gold. Your typical refractory ore contains tiny inclusions, or submicroscopic gold, within a sulphide mineral matrix, requiring physical and chemical altering of the mineral matrix .

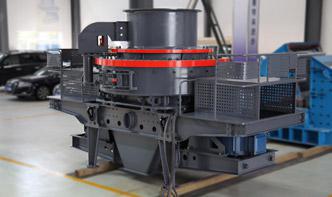

GS5000 Gold Stryker Gold Ore Impact Flail Processing Rock ...

Our Gold Stryker® GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons of ( inch) rock in a day, all the way down to #300 mesh through the mill to release the gold. Perfect for the small gold mining operation.

From Tailings to Treasure? A New Mother ...

· DRD Gold extracted 33,600 ounces of gold, worth nearly US40 million, in the last quarter of 2013. Mintails, a mine tailings processor, has developed new technology to process 350,000 tons of slimes from its extensive tailings resources. It expects to recover 58 kg of gold per month, and has enough slimes to last until 2025.

Top ten gold producers in Zimbabwe 2019

· These are the top ten gold producers in Zimbabwe. 1. Freda Rebecca. Freda Rebecca is the largest gold producer in Zimbabwe. It's loed close to Bindura's Trojan Nickel mine, 90km north of Harare. It mines 3,000 tonnes of ore and removes 8,000 bank of overburden on an average every day.

Gold extraction

Gold ore can be classified as freemilling, complex, or refractory and each type of ore has different challenges when it comes to processing methods. Cyanidation with CIL/ CIP continues to be the most common method, although there are environmental concerns due to toxicity. As mining companies continue to face pressure to reduce environmental impact, and as free .

Best Online Shopping Store in Oman | Buy Electronics ...

If you are looking for the best online shopping store in Oman which is userfriendly, reliable, secure and dynamic, then you are at the right place. Here, you can shop from anywhere at any time and choose from a wide range of products to fulfill all your shopping desires. Providing customer delight at every step of the process is our goal in order to ensure a seamless .

Heap Leach: Mining's breakthrough technology

· Downsides of the process are 1) low predictability of process performance as "hidden factors" abound in comparison with milling CIL/CIP, 2) lower recovery rates – not good for highgrade ...

Toll Milling and Mineral Processing

Toll milling is the exchange of custom milling services and other processing services for a fee or toll. This guide is a review of some of the machines used in African Pegmatite's cuttingedge milling facilities which are available on a toll basis to businesses. By familiarising themselves with this equipment, businesses can get a better understanding of what services and machines .

Smallscale gold miners in DRC challenge the view that ...

· Smallscale gold miners in DRC challenge the view that they can't cut it. Artisanal and smallscale mining in Africa has grown significantly in recent decades. Between 1999 and 2019, the estimated ...

Toll Processing Services

All of our milling and toll processing rooms operate under a negative pressure and many mills have ceramic abrasion resistant linings to help limit introduction of foreign particulates. Our air compressors are humidity controlled and dust scavenging systems are in place in each production cell as an added precaution. As our customers supply much of the materials processed at .

Gold and Tailings: The Standard Mill at Bodie, California ...

The process of treating gold ore to extract gold (and silver) and, therefore, produce bullion is called milling. The building housing the process is called a mill. The finely pulverized material that is rejected from the mill after the gold has been extracted is called tailings. Operators of mills exhibited keen interest in tailings, the waste product of their milling process. Mill operators ...

Stories

THE STORY OF KIROV'S MILL IN RUSSIAThrough challenges and difficulties to success. Kirov's Mill is the leading flour milling enterprise in Russia and the largest mill in Europe. Today the company produces more than 40 types of specialpurpose flours, as well as semolina, grist, bran and flaked grain. The mill can process up to 1,650 tons.

Gold Extraction Recovery Processes

· SAG mill circuit. Gold Recovery. Gold recovery comprises similar stages to the processing of most ores. First, the valuable minerals are separated from the gangue through concentration. The final concentrate is obtained by repeated processing and is smelted or leached in order to get a Dore bar. In generals, the concentration of gold includes three .

4 Processes To Extract Gold From Its Ore

· Extract gold from its ore has a long history in our human history, which can be dating back to sometime around BC. And we may still remember some notable Gold Rushes in recent centuries.. In the modern mining industry, washing and extracting gold is not a oneoff process.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك