horizontal bead mill working principle

ترك تعليقك

HorizontalAxis Wind Turbine (HAWT) Working Principle ...

HorizontalAxis Wind Turbine Working Principle. The horizontalaxis wind turbine (HAWT) is a wind turbine in which the main rotor shaft is pointed in the direction of the wind to extract power. The principal components of a basic HAWT are shown in Figure 1. The rotor receives energy from the wind and produces a torque on a lowspeed shaft.

Bead Mill for Paint and Coating Industry

KARVIL: Your Reliable Bead Mill Machinery Supplier in China. KARVIL disc type bead mill has been widely applied in production of industries like paint, color paste, ink, papermaking, adhesive, drugs and chemical material, etc. Working Principle

horizontal bead mill working principle

Lab horizontal bead mill is an advanced wet process bead grinding machine for milling and dispersing to reduce particle size for paints, inks, pigment dispersion and other chemicals It realizes high milling efficiency and fine milling effect, Working Principle Motor driven feeding device internal high speed rotation, a negative pressure ...

Effect of the milling parameters on the product dispersity ...

The aim of the research was to investigate the airtransported working principle in case of a horizontal stirred media mill and to install the laboratory scale mill and the additional systems. During the measurements the mill was operated in open circuit mode, the feed model material was limestone. The effect of the feed rate,

horizontal bead mill working principle

horizontal bead mill working principle. FOB Reference Price: Get Latest Price Description: The working principle is that a shaft fitted with grinding discs, rotates within a fixed grinding chamber that has been charged with the chosen grinding beads. ... Horizontal bead mills or agitator ball mills with a horizontal grinding chamber do not have these advantages and are thereby ...

DMQXSeries

DMQX ® Horizontal Bead Milling Systems are available in either Lab or Production Models.. Scroll down for more details on our bead mills, or contact us now for the right circulation grinding systems for your operation. Rail system allows for easy maintenance and tank removal. Hinged door for easy access to grinding chamber.

Influence of processing parameters on disintegration of ...

· Industrially relevant are horizontal bead mills (Kula and Schütte 1987; Middelberg 1995) originally designed for the homogenization and size reduction of different commercial products such as milk and paint. The principle of bead mills is based on rapid stirring of a thickened suspension of microorganisms in the presence of beads.

Grinding System Discus

Optimum Grinding Bead Activation TetraNex ® – The grinding system for optimum energy input. The NETZSCH Discus agitator bead mills are equipped with the TetraNex ® grinding system. The TetraNex ® grinding disk, which replaces the familiar TriNex ® grinding disk, is available in the standard design and in the TetraNex ® Plus version. While the front side of the standard .

What is Horizontal Boring Machine and How it Works ...

· A Horizontal Boring Machine has a work spindle parallel to the ground and work table. The tool head and part move typically along three linear axes. The main axis that drives the part towards the work spindle is the Zaxis, with a crosstraversing Xaxis and a vertically traversing Yaxis.

working principle of milling process

The working principle and milling process of bead mill. Driven by the force of dispersion devices, grinding media and material are contacting and material is crushed and ground into ultrafine size by shearing, pressing force of zirconia beads.

Choosing the Best Media Mill For Your Wet Grinding ...

· The massspecific energy is the work required to mill a quantity of product to a desired grinding specifiion. ... by increasing the number of beads or points of contact in the mill one will increase the opportunity for collision and shearing between the bead and the pigment particle. ... The trials were performed on a 10liter horizontal ...

horizontal bead mill working principle

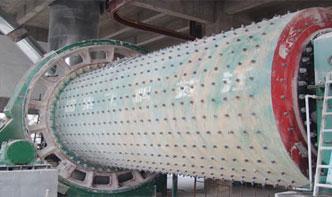

Working Principle of Bead mill. Bead Mill Working Principle: The bead mill consists of a horizontal grinding chamber, which in turn houses the shaft and agitator discs. The chamber is filled with zirconium grinding media and the material leakage is prevented by the double acting mechanical seal.

Geometry influence on optimized operation of a dry ...

· Altun et al. (2013) investigated a horizontal dry agitator bead mill prototype in 2012 and described the influence of various process parameters for the system. The basis for this is the very well known principle of working with agitators and grinding media. However, in typical, wellknown stirred media mills the particles were present in a ...

Working Principle of Bead mill

Bead Mill Working Principle. The bead mill consists of a horizontal grinding chamber, which in turn houses the shaft and agitator discs. The chamber is filled with zirconium grinding media and the material leakage is prevented by the double acting mechanical seal. The material is pumped into the chamber using a air operated diaphragm pump or ...

Ball Milling The Role of Media and Bead Mills

Horizontal Bead Mills: Our Dispermat SL model line is the current horizontal bead mill system. Milling chamber sizes can start at 50 ml to save on raw material costs. The beads are separated from the mill base by a dynamic gap system. The standard gap uses mm diameter grinding media; an optional gap is available to use beads down to mm ...

IsaMill

MIM decided to work with Netzsch, which was a pioneer in the fine grinding field, and still a leader. Test work was undertaken using one of Netzsch's horizontal bead mills. It showed that such a mill could achieve the required grind size. However, the mills used in these industries were used on a small scale and were often batch operations.

CLASSIFICATION OF MILLS USED IN PHARMA INDUSTRY

· A given mill may operate successfully in more than one class: a hammer mill may be used to prepare a 16mesh granulation and to mill a crystalline material to a 120mesh powder. The mills used for size reduction of the granules can be divided into two primary egories based on the energy input into the process.

Bead Mill, Principle and Appliions / Apex Mill series ...

The orientation of the mill is an item for selection of the type of bead mill. There are two types of bead mills: horizontal and vertical. Since the centrifugal force acting on the beads is tens to hundreds times the gravity, the influence of gravity is small enough to be ignored.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك