copper smelting and refinery process

ترك تعليقك

Copper Smelting Process

Offer helpful instructions and related details about Copper Smelting Process make it easier for users to find business information than ever

NEW CONTINUOUS SMELTING AND REFINING PROCESS FOR COPPER .

· Contimelt is a new twostage process for melting and refining copper. Compared to the traditional batchwise operated reverberatory refining furnace, Contimelt represents a continuous operation with a high melting/refining rate, saving energy and manhours and allowing close environmental control.

Refinery

Copper anodes and SS blanks are inserted in altenatively electrorefining cells. By applying direct current to this cell, copper in anode is dissolved and deposited onto the SSblank surface. Cu % in hode is more than %. By products at Refinery are anode slime and copper telluride.

Refining – Various Methods

Usually, it is a copper refining process against impurities. Firstly, the impure copper is kept in an anode furnace for two steps of refining. Next, iron and sulphur release in the form of iron oxide and sulphur oxide by blowing air. In this step, the iron oxides release from copper and gaseous sulphur oxide emits from furnace by offgas system.

Smelting and Refining Copper in Chile: The Importance of ...

Smelting and refining all the copper ore in Chile on the one hand helps to reduce global greenhouse gas (GHG) emissions (Sturla et al., 2020), but on the other hand, by concentrating this process in one country (in spite of 12 countries), greatly affects the

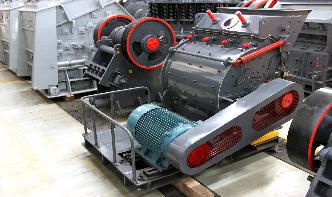

Copper Smelting Slag Recovery

Rotary Reverberatory Furnace Smelting. The furnace can be designed with effective working volume minimal, suitable for the recovery of anode slime, PMcontaining smelting slag, lead refining dross and all kinds of dust. It can also treat secondary material like scrap copper, WEEE/PCB/IC and etc. Lead Anode Slime.

(PDF) Primary Copper Smelter and Refinery as a Recycling ...

· According to Anindya et al., Montanwerke Brixlegg smelter has published distribution ratio of tin into metal, slag, and fume in the secondary copper smelting process, and its ratio is calculated ...

Primary Copper Smelting

Copper is produced in the U. S. primarily by pyrometallurgical smelting methods. Pyrometallurgical techniques use heat to separate copper from copper sulfide ore concentrates. Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. Process Description24 Mining produces ...

copper refining process

Copper Production Copper The next step in the process flow is smelting for sulfide ore concentrate and solvent extraction for oxide ore leach solution 6 Refining Inquire Now Copper Refining: From Ore to Market | Investing News

Chapter 7 Energy Use in the Copper Industry

and smelting, converting, and refining the remaining 40 percent. Actual requirements vary widely depending on the mine characteristics and type of smelter, however. Table71 shows one estimate of energy requirementsin Btu equiva lents for a hypothetical copper operation. It is interesting to note that pollution control equals a

Copper Dross

Refining dross is the result of lead refining process where impurities like copper, tellurium, arsenicantimonytin, silver, zinc and bismuth in sequence from lead bullion. There are many types and composition of each type of dross varies and is subjected to specific refining steps and raw material contents.

Our process | Umicore Precious Metals Refining | Umicore

The main processing steps of the Precious Metals Operations are the smelter, the copper leaching and electrowinning plant and the precious metals refinery. The operations are designed in such a way that raw materials can enter the flowsheet at the most optimal process step, determined by their physical aspect, their analytical fingerprint and their (precious metals) value.

Focused on copper

Since completion of the Group restructuring on 31 October 2014 KAZ Minerals no longer carries out smelting and refining activities internally, instead sending copper concentrate directly to export markets or to external providers of smelting and refining services in Kazakhstan.

Copper extraction

Copper extraction refers to the methods used to obtain copper from its conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.. As in all mining operations, the ore must usually be beneficiated (concentrated).

copper processing

Roasting, smelting, and converting Once a concentrate has been produced containing copper and other metals of value (such as gold and silver), the next step is to remove impurity elements. In older processes the concentrate, containing between 5 and 10 percent water, is first roasted in a cylindrical, refractorylined furnace of either the hearth or fluidizedbed type.

Copper

Copper. We are one of the world's largest producers and marketers of copper. In 2020, we produced million tonnes, and sold million tonnes through our marketing business. We mine and process copper ore in the key mining regions of Africa, Australia and South America. We source and recycle copper scrap in North America and Asia.

CESL COPPER PROCESS – AN ECONOMIC ALTERNATIVE TO SMELTING

CESL COPPER PROCESS – AN ECONOMIC ALTERNATIVE TO SMELTING Glenn Barr, Jennifer Defreyne, Keith Mayhew CESL Engineering ABSTRACT Cominco Engineering Services Ltd (CESL), a subsidiary of Teck Cominco Metals Ltd, has developed proprietary hydrometallurgical processes for the treatment of nickel, copper and coppergold concentrates.

NEW CONTINUOUS SMELTING AND REFINING PROCESS FOR COPPER .

Contimelt is a new twostage process for melting and refining copper. Compared to the traditional batchwise operated reverberatory refining furnace, Contimelt represents a continuous operation with a high melting/refining rate, saving energy and manhours and allowing close environmental control.

Final

The EHS Guidelines for Smelting Refining cover information relevant to base metal smelting and refining of lead, zinc, copper, nickel, and aluminum. It does not include the mining and concentration of the raw materials, which is covered in the EHS Guidelines for Mining. Annex A contains a description of industry sector activities.

primary copper smelting process

· Primary Smelting and Refining of Copper 1997EconomicCensus Manufacturing IndustrySeries 1997 IssuedDecember1999, coordination of the publiion process Kim Credito, Patrick Duck, Chip Murph,, separate industry classifiion based on its primary activity and not that of its parent company...

What Is Copper Smelting? (with pictures)

· One of the main side effects of the copper smelting process is the production of waste. Refining copper results in three and a half times as much waste as the amount of copper produced. This waste is not only in the form of solids that must be disposed of or recycled, but also sulfur dioxide gas.

(PDF) Reducing agents in fire refining of copper ...

Reducing agents in fire refining of copper — analysis of the reduction process and its costs (Journal: Rudy i Metale Nieżelazne, vol. 58, issue 12, 2013)

Copper Refining: Explained StepbyStep

· In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing smelting in order to eliminate the common impurities, most of which have a stronger affinity for oxygen than has these operations some of the copper is oxidized to cuprous oxide and dissolved by .

Miners, smelters still divided on copper processing ...

· Miners pay smelters treatment and refining charges (TC/RCs) to process copper concentrate into refined metal. The first settlement between a major copper miner and a Chinese smelter in the annual ...

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك