pulverized coke process

ترك تعليقك

The Steel Making Industry

Pulverized coal can be substituted for coke at nearly a 1:1 and can replace 25 40% of coke traditionally used in furnaces (USEPA, 1995). Pulverized coal injection is used worldwide to reduce coke use and, thus, coke emissions (Chatterjee, 1995). Pulverized coal injection may affect the final steel products. Pulverized coal may reduce gas ...

(PDF) Coal Blending with Petroleum Coke in a Pulverized ...

Coal Blending with Petroleum Coke in a PulverizedFuel Power Plant. Energy Fuels, 2005. Angeles Borrego. Rosa Menéndez. Diego Alvarez. Henrik Petersen. Katia Milenkova. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper. 34 Full PDFs related to this paper.

ALL ABOUT BLAST FURNACE

Jul 16, 2017 · Pulverized Coal Injection (PCI) is a process that involves injecting large volumes of fine coal particles into the raceway of a blast furnace (BF). This provides not only a supplemental carbon source but also speeds up the production of liquid iron besides reducing the need for metallurgical coke for reactions in the blast furnace.

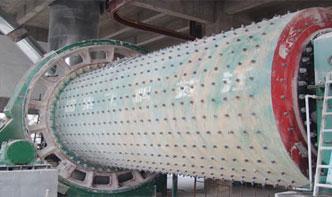

Pulverizer

The material to be pulverized is introduced into the center or side of the pulverizer (depending on the design). As the lower ring rotates, the balls to orbit between the upper and lower rings, and balls roll over the bed of coal on the lower ring. The pulverized material is carried out of the mill by the flow of air moving through it.

Pulverized coal burners

In burners of all three types, highdensity pulverized coal is injected through pipes (76 or 89 mm in diameter) with splitters at the end. Central and peripheral air passages have axial swirlers. Natural or coke gas is injected into burners via gas tubes .

The efficient alternative Fuel. Petroleum coke‐ for Steam ...

Petcoke has become a competitive fuel, which has made it very popular in Process / Power boilers. Petroleum coke basically comes in two types named the fluid coke and delayed coke. Fluid coke is typically left with / contains about 5 % volatiles and because of its small particle size is not generally very suitable for combustion in AFBC boilers.

Kiln burners

The primary fuel is typically pulverized coal or coal+coke, with the option to burn natural gas or fuel oil. Either natural gas or fuel oil can be ignited directly by the integral ignition system. Typically, natural gas or fuel oil is be used to heat up the rotary kiln and then ignite the coal flame, but either may be used to fire the kiln up ...

Pulverized Coal Briquetting MachineFote Machinery ...

Introduction of Pulverized Coal Briquetting Machine. Pulverized coal briquetting machine is a kind of equipment which can press powdered materials into balls, such as pulverized coal, slime, medium coal, coke powder, coke coal and metallurgical powder, refractory materials, and so .

Ironmaking 101 – From Ore to Iron with Blast Furnaces ...

Oct 10, 2017 · Coke is made in a coking oven by heating hard coal in the absence of air or oxygen. The iron ore can be ground further to a fine powder mixed with a fluxing agent (limestone), fine pulverized coke (coke breeze) and a binder, which is formed into granules or pellets and sometimes cooked or sintered to form sinter.

Meeting a burning need for cleaner steelmaking

Testing a newly designed twostage coke oven Credit: ... are going to great lengths to revolutionize the steelmaking process, making it cleaner and more efficient. ...

Inhibiting effects investigation of pulverized coal ...

2 days ago · The oxidation process of pulverized coal was changed after the addition of MCA. Without the MCA, the maximum mass loss rate and heat release of the pulverized coal oxidation were %/min and J/g, respectively. When 50% MCA was added, these parameters were %/min and J/g, respectively.

Coke Making in Byproduct Coke Oven Batteries

Apr 15, 2019 · Most coke in the world is produced in a Byproduct Coke Oven Batteries and is an integral part of an iron and steel industry. The manufacture of coke by heating coal in absence of air has its origins at the start of industrial revolution . Coal is converted to coke in large coke oven batteries by the destructive distillation of coal. Process

pulverized coal injection coking coal and anthracite

Pulverized Coal Injection Coking Coal And Anthracite. pci coal is generally used for sintering, smelting and injection purposes in the pulverized coal injection process in iron production. about coal colonialcoal. from highest quality to lowest quality they are hard coking coal, semisoft coking coal, and pulverized coal injection (pci) (or low volatile pulverized coal lvpci injection).

SciHub | CaC2 Production from Pulverized Coke and CaO at ...

CaC2 Production from Pulverized Coke and CaO at Low Temperatures—Influence of Minerals in CoalDerived Coke. Industrial Engineering Chemistry Research, 51(33), 10748–10754. doi:/ie

Pulverized Coal Injection

The first dense phase distributor system in 1984. 52 pulverized coal injection systems for blast furnaces. Coal injection systems with 15 million tons per year total capacity. The world's largest coal grinding and injection system with a today's capacity of 320 t/h to ILVA, Taranto in Italy. File Name. Size. Claudius Peters PCI Brochure. 1 ...

Graphite manufacturing process

Jun 13, 2020 · Raw materials for synthetic graphite fabriion (petroleum coke, pitch coke, carbon black, natural graphite and secondary graphite scrap are loaded and stored in raw materials silos. At the first step the raw materials are pulverized (ground) in .

Coal Blending with Petroleum Coke in a PulverizedFuel ...

Dec 30, 2004 · The current work investigates the performance of petroleum coke (PC) as a blended fuel under pulverizedfuel combustion conditions. Three fullscale combustion experiments were carried out: a pure Carboniferous, high volatile bituminous coal and two blends of this coal with different proportions of PC. The samples studied included feed fuels and .

Fluid and FlexiCoking | FSC 432: Petroleum Refining

Fluid coking can process heavier VDR and gives a higher distillate yield (and lower coke yield) than delayed coking. Figure shows a schematic diagram of flexicoking. A gasifier is added for conversion of some or all coke produced in the coker in .

What is meant by pulverized coal?

May 11, 2020 · A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.

Rapid Pyrolysis of Pulverized Coal for the Preparation of ...

By rapid pyrolysis of pulverized coal in oxygen and steam atmosphere, powder activated coke (PAC) nanostructured carbon material was derived by one step. Then, nitrogen adsorption measurement, scanning electric measurement (SEM) and Fourier transform infrared spectroscopy (FTIR) test were conducted to analyse the detail characteristic of the obtained PACs.

Coke :Manufacturing from Coal

Non byproduct coke ovens burn the hydrocarbon off gasses produced by the coke making process to drive the carbonization process. Coke is used as a fuel and as a reducing agent in smelting iron ore in a blast furnace. Coke may be used to make fuel gases.

Needle coke production process

Jan 08, 2021 · The production process mainly includes three stages: raw material pretreatment, delayed coking, and calcination. The coking process is a key stage in the production of needle coke. The coking temperature is one of the most critical factors affecting the quality of needle coke. If the calcination technology is relatively mature, plants only need ...

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك