final grinding ball mill

ترك تعليقك

Zhengyuan Powder Equipment

Laboratory Equipment. Others. Powder Processing. LHMB Ball Mill. The ceramic media ball milling production line is the best solution for processing highpurity materials. It is specially designed for highpurity materials: the grinding lining and media are made of corundum, cobblestone, quartz, zirconia, etc. LHMA Ball Mill.

Ultrafine Grinding with Laboratory Ball Mills

grinding balls mm Ø, 10 g sample, 15 ml 1% sodium phosphate). After 30 minutes the d90 value of the Emax sample was 87 nm. The planetary ball mill achieved a grind size of only 476 nm after this time (excl. cooling breaks). Consequently, the Emax provided a 5 times higher final fineness than the planetary ball mill (fig. 9).

PRACTICAL 1: BALL MILLING

· The longer the duration for ball milling, smaller the final particle size. Grinding concentration also affect the process of ball milling. When the grinding concentration is 55%, the negative cumulative yield rate of a onelevel in product is the smallest, when the mill mineral concentration of 70%, the viscosity of the slurry is density and ...

Grinding and Milling Systems Course

The segmentation of grinding and milling systems. Module 2 – Ball mills. This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and ...

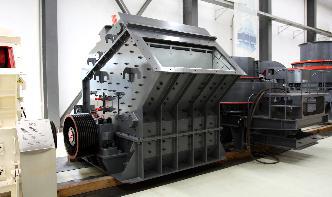

Mineral Grinding Ball Mill Manufacturers ...

special dust collector. We are committed to providing quality products and excellentaftersale service and support. Our Mineral Grinding Ball Mill comes with several features that are beneficial for the industry. Our machine is best suited for grinding materials with high hardness; the shape of the final products delivered by the machine is circular, consistent performance .

Ball Mill at Thomas Scientific

.GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials. The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills. It has a single grinding station for.

Bond Grinding Test Mill – Esmic Engineering Systems Limited

Description. LiyaTest Feeding Size: < 8 mm*, Feed quantity ml, Final Fineness: < 40 μm*, Dijital setting of grinding revolutions from 0 up to 9999 revs., Rotation speed infinitely variable between 0100 rpm, Jar made of AISI 304 stainless steel, Ø305×305 mm 22 L internal volume., Equipped with one main and one spare charge of ...

Grind

Molycop manufactures grinding balls to exacting internal specifiions at its grinding media production facility across the globe. Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using .

Planetary Ball Mill BM40Beijing Grinder instrument ...

· When the planetary ball mill starts, the motor drives the common sun wheel to move, while the grinding jars, which are loed on the sun wheel, turning around its own axis. The direction of the movement of the sun wheel is opposite to that of the grinding jars in the ration 1: grinding balls in the grinding jars are subjected to ...

What is planetary ball milling? – Morethingsjapanese

· The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls. Ball mills grind material by impact and attrition. The degree of milling in a ball mill is influenced by; a. How do you calculate ball mill power? The grindingproduct size, P, in a Bond ball ...

Milling | Ball Milling tables

The working principle of the vibratory grinding mill is based on intense motion of the grinding balls, with both inertia and centrifugal forces. The energy produced using the Sweco mill is higher than that produced by the ball mill, making it more effective in .

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL ...

operating parameters. Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study. It is hoped that the analysis of the data acquired will allow insight as to which parameters will require a functional form if they were to be integrated into a complete liberation model. · ...

Ball mill performance improvement

· The ball mill is key equipment in grinding industry. It is widely used for the cement, coal, sand, fertilizer, glass, ceramics etc. But its final product cost .

LABORATORY GRINDING MILLS

mill." The operation of an Attritor is simple and effective. The material to be ground is placed in a stationary tank with the grinding media. Carbon steel, stainless steel, chrome steel, tungsten carbide, and ceramic balls are commonly used media. The material and media are then agitated by a shaft with arms, rotating at high speed.

Planetary Ball Mill BM6ProBeijing Grinder instrument ...

· Planetary Ball Mill BM6Pro is suitable for grinding (drywet) and mixing some soft,hard,brittle and fibrous samples,which is used wherever the highest degree of fineness as customer required,as well as the grinding result is reproducible. Apart from the classical mixing and size reduction processes,the mills also meet all the technical ...

Dry Ball Mill for Sale | Buy Dry Grinding Ball Mill with ...

Dry ball mill is a grinding equipment that uses dry ball milling process to grind materials. Different from the wet ball mill, the dry ball mill does not need to add water when performing the grinding operation, only relying on the impact and crushing effect of the grinding media on the material to grind the material.. The finished material of the dry grinding ball mill is dry .

Ball Mill

Ball mill is an idle tool for grinding many materials into fine powder and it is used to grind different kinds of row are two ways of grinding, first is dry process and second is wet process. It are often divided into tubular type and flowing type consistent with various sorts of discharging material.

6 Reasons Why Output of Ball Mill Decreases

· In addition, whether the final product of ball mill is solid solution, intermetallic compound, nanocrystalline oramorphous phase, all of the them involve the problem of diffusion, which is also affected by the grinding temperature, so temperature is also an important factor affecting the output of ball mill. 5.

Resminer Grinding Ball

into fine powder. Grinding balls are small balls that grind the material inside the ball mill by crushing and grinding it. Balls made of stainless steel or ceramics are typically used for grinding. Ball mills rotate so the balls crush and grind the material inside, creating loose powder as a result.

Kyanite processing grinding millStone Grinding Mills ...

Features of HGM series micro powder grinding mill: 1. High efficiency Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill. 2. Long life cycle of spare parts The ring and roller are forged by special material with high utilization.

Ball Mill Roller Press Systems for Cement Grinding ...

The coarse part is returned to the roller press for crushing once again; the medium fine part is sent to the ball mill for final grinding; and the fine part is discharged directly as the finished product cement. Because the roller press and the ball mill are two separate circulate system, the whole cement grinding process is easy to operate and ...

Ball Mill Grinding,Ball Mill,ball grinding mill

Ball Grinding Mill. Capacity:20200 T/H. Feeding size:25 Mm. Output Size:30400 Mesh. Brief Introduction of Ball Mill Grinding: Ball mill Grinding can divide into 2 types, wet ball mill grinding and dry ball mill grinding. Ball mill grinding is a mineral processing machine for milling the materials into powders after they are crushed. It ...

FLS TMS2010 Final

This option reduces the occurrence of very fine particle in the plant feed that occur due to overgrinding in the grinding circuit. Such options have been considered for SAG and SAG/Ball circuits. Figure 9. 26' x 16', 4850 kW SAG mill in bauxite grinding Figure 11. Typical 5m x, 1300 kW Drum Scrubber Appliion.

Ball Mill for Sale | Grinding Machine

Ball mill is a key equipment for grinding materials. thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing. our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc ore, copper, etc.. JXSC Mining produce reliable effective ball mill for long .

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك