iron ore fines agglomeration

ترك تعليقك

Metals | Free FullText | Nucleation and Growth of Iron ...

Jul 04, 2019 · However, sometimes whiskers can cause problems, such as metal whiskers in electronic components can cause short circuit, iron whiskers produced during gasbased reduction of iron ore fines will cause the agglomeration of iron ore particles.

Sintering plant at a glance

Oct 27, 2014 · 18 WHAT IS SINTER • Sintering is the process of agglomeration of iron ore fines into a porous mass by incipient fusion heat generated within the mass itself. 19. 19 TYPES OF SINTER • Depending upon weather bases have been incorporated in the Sinter mix, sinters are divided into three broad classes: (i) Non Fluxed OR ACID SINTERS: Those ...

Iron and Steel

If your mills are accumulating mountains of minus 3mm fines with varying moisture levels, then you're in our sweet spot and we should talk. For more information on Steele byproduct management for iron and steel mills, talk to your regional Steele sales representative or call +

WOA1

A microagglomerate of fines of a material that is predominantly titanium dioxide in which the fines are bound in the microagglomerate by a polysaccharide gum or cellulose derivative and in which the microagglomerate has been heated in the temperature range 250600ºC so that the polysaccharide gum or cellulose derivative is an effective primary binder of the fines when the .

manganese ore of any grade and iron ore fines

Agglomeration In Iron Ore. ensp0183enspin steel industry and in mines a significant amount of ultrafines waste iron oxides and iron ore fines is generated. utiliations of these fines are required to reduce the environmental haards and conserve the natural resources. some of these fines are normally used in sintering practice.

Reduction Behavior and Structural Evolution of Iron Ores ...

Sep 28, 2015 · These are direct reduction and smelting reduction technologies, some using iron ore fines directly without prior agglomeration processes. This work deals with the development of a new method for the investigation of reduction behavior and structural evolution of iron ore fines under fluidized bed conditions – in order to optimize fluidized ...

Untitled Document []

With the adoption of mechanized mining and close sizing of ore, the amount of fines generated in the mines has increased substantially, thereby emphasizing the need for their agglomeration. This subgroup focuses on the sintering and pelletizing techniques for agglomerating ore fines for metallurgical appliions.

Proceedings of the 4th international symposium on ...

Papers presented discussed pelletizing of coal fines, graphite manufacture, compacting of coal, use of computers in agglomeration, HYLIII process, briquetting of iron ore fines, RECLAFORM, INMETCO process, binders for agglomeration, acoustic agglomeration, pelletizing of limefly ash mixtures, extrusion of aluminas for alysts, and ...

Benefit Of Agglomeration Of Iron Ore

The Sintering Process of Iron Ore Fines ispatguru agglomeration of iron ore fines process,Mar 9, 2013 The Sintering Process of Iron Ore Fines Sintering plants are normally It is basically an agglomeration process achieved through combustionIron Sintering POPs Stockholm Convention on Persistent Organic The sintering process is a pre .

Manganese Ore Fines Agglomeration

Manganese Ore in the country are placed at 378 million .. MOIL has also plans to set up agglomeration facilities by sintering of manganese ore fines to. The Development of an Agglomerate Through the Use of FeMn .. Manganese (FeMn) metal fines profitably. . ultra ore fines and ΠGloria and Nchwaning sludge. ..

Innovative Development on Agglomeration of Iron Ore Fines ...

Download Citation | Innovative Development on Agglomeration of Iron Ore Fines and Iron Oxide Wastes | In steel industry and in mines, a significant amount of ultrafines waste iron oxides and iron ...

sponge iron fines sales

Sponge iron fines sales can be recycled through agglomeration and pelletizing, with a tonnage of around 20,000 tons per month. The sale of sponge iron fines and sponge iron sludge is carried out by direct reduction factories, due to the development of briquetting and agglomeration processes in the steel industry.. Fortunately, the methods of the day are a way to restore the .

After the benefiion of iron ore fine concentrate can ...

20 PELLETIZING • Fine iron ore concentrate is mixed with a binder and water to produce pellets using a pelletizer, typically a drum or disc. These green pellets are dried at temperatures around 105 o C. Most pellets are then heated to a temperature of 1200–1300 o C to become hard enough to withstand storage and handling. • Similar to sintering, pelletizing is another widely used .

LowCarbon Production of Iron Steel: Technology Options ...

Mar 08, 2021 · Other assumptions that may be applied include (1) zerocarbon electricity supply, (2) ore fines to avoid agglomeration, (3) fine coal to avoid coking. Combining these approaches could eliminate CO2 emission from coking, sintering, and pelletizing completely, yielding in maximumly 20% CO2 decrease for a facility.

Carboncomposite briquetting of iron ore fines fast ...

Iron ore fines coal fines are mixed on the basis of stoichiometric ratios of carbon oxygen, with some excess carbon. The process makes it possible to use iron ore fines coal fines without any expensive agglomeration processes, such as pelletisation or sintering.

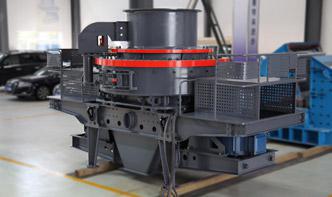

Highpressure briquetting of iron ore fines – GoodRich ...

GoodRich offers highpressure briquetting plant from a specialized manufacturer in China, to briquette iron ore fines. These briquettes can be used in the rotary kilns for making sponge iron. Briquetting is an agglomeration process, similar to pelletizing or sintering, but without the need for thermal processing.

High Efficient MXV15 Iron Ore Fines Mixer / Iron Ore ...

YECHUANG MT intensive mixers are widely used in iron ore pellet it's unique working principles and overwhelming prior mixing efficiency,the homogeneity of mixing could largely reduce bentonite consumption,increase the green ball strength and cut down the returning using YECHUANG MT intensive mixers,bentonite consumption can even lower to .

Iron Ore Beneficiation | Primetals Technologies

Agglomeration; Iron Ore Beneficiation; ... This enhances the frequency of contacts between the gas bubbles and very fine particles, which optimizes recovery of fines and increases the yield. In addition, the columnar section of the unique hybrid design ensures a second scavenging flotation stage for the particles, which also contributes to ...

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك