roller press ball mills optimisation

ترك تعليقك

Engineering | Industrial Ally

Extensive Experience with Grinding Systems (Ball Mills, Vertical Mills, Roller Press) Mechanical Industrial Ally's Mechanical Engineering Team includes a combination of experienced Engineers and Designers who stay at the forefront of modern technology, while leveraging the team's nearly 100 years of combined Cement Industry experience to provide:

Roller Presses

Roller Presses: roller support. A question of the right bearings. Roller Press rolls and bearings. In KHD Roller Presses, the rollers are supported in radial, multirow cylindrical roller bearings. This ensures an even load distribution on the roller .

Ball Mill Optimisation In Plant

Vertical Roller Mill Optimisation. Ball mill optimisation in cement plant a cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball.

Troubleshooting roll defects

Observed only after the roll has started to be unwound. Nonuniform crossdeckle caliper: Reduce crossdeckle caliper variation. Winding too soft at same radius of the roll with respect to other radius: Control hardness of wind throughout the problem area. Excessive web tension while winding: Reduce web tension.

roller mill optimisation

roller press ball mills optimisation. vertical cement mill optimization. The Optimization In Roller Mill In Cement Industry. Cement Grinding Vertical Roller Mills Versus Ball Mills. Cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and ...

Roller Press Ball Mills Optimisationball Mill

Optimizing raw mills performance the materials wayoptimizing raw mills performance the materials wayGenerally roller mills can accommodate high size up to 80100 mm and high moisture 20 whereas ball mills can normally accommodate up to 25 mm moisture up to 12, roller press ball mills optimisation

PTC:022 Methods for Design and Optimisation of Ball Mill ...

PTC:022. Methods for Design and Optimisation of Ball Mill and Other Grinding Circuits, Classifiers and Cyclones. This is a comprehensive report especially useful for all such industries which employ dry or wet ball mills, other grinding mills like roller mills, roll presses, hammer mills, crushers, classifiers, cyclones, hydrocyclones etc., equipment manufacturers, .

International Cement Review Advertising | International ...

Size: 63mm (w) x 84mm (H) The eighthpage vertical advert sits within the editorial page template. Download template: Adobe Indesign. Adobe Illustrator. Adobe PDF. International Cement Review is an essential part our marketing mix – offering us 360 degree access to our target audiences on print, digital and events.

MACHINING OPERATIONS AND MACHINE TOOLS

• Drill press – Upright drill – Bench drill – Radial drill – Gang drill 26 drills together – NC drill • Vice, Jig and fixture. 11. 3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types – Peripheral milling • Slab, slotting ...

FROM INCREASING CEMENT PLANT RELIABILITY TO SUSTAINABLE ...

ROLLER PRESS High loads Shock loading Roller bearings: Shell Gadus S2 V1000AD Shell Shell Gadus S4 V2600AD * Motors Gearbox Hydraulics 3. CONVEYOR Continuous operation Dusty Roller bearings – manual lubriion: ... HORIZONTAL FINISHING BALL MILL** UNINTERRUPTED PRODUCTION

(PDF) Performance Evaluation of Vertical Roller Mill in ...

In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were compared. ... Working press. Mroller (bar) 94. 94. Classifier rotor speed (1/min ...

Taking Process Control to The Next Level | Rockwell ...

· Finish mill #11 was a standard ball mill, capable of producing approximately 90 tons per hour of type I/II cement. Finish mill #10 was a ball mill configured with a roller press for pregrinding, capable of producing approximately 130 tons per hour of type I/II cement.

Ball milling: a green technology for the preparation and ...

Ball milling is a simple, fast, costeffective green technology with enormous potential. One of the most interesting appliions of this technology in the field of cellulose is the preparation and the chemical modifiion of cellulose nanocrystals and nanofibers. Although a number of studies have been repo Recent Review Articles Nanoscale Advances Most Popular Articles

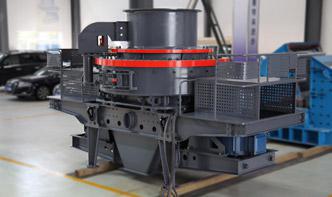

ball mills optimisation parties

ball mills optimisation parties . GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio. From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirements.

Practical 1 : Ball Milling

· In roller mills, the principle of attrition is used where material is sheared as it passes through a gap and is transferred from slower roll to a faster roll, and is removed by a scraper. In ball mill, size reduction is done by both impact and attrition of particles. Rod mill is similar to ball mills but it uses long rods for grinding media.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك