grinding mills fill ratio in lime slaking

ترك تعليقك

Grinding Mills Fill Ratio In Lime Slaking

Grinding Mills Fill Ratio In Lime Slaking. Processing ability:2120t/h. Feeding size: ≤15≤30mm. Product granularity: ≤15≤30mm. High pressure grinding mill can grind stone into powder that commonly used in chemical plant or a power plant, etc.

ball mills fill ratio in lime slaking

mills fill ratio lime. Ball mill in lime slakingmining ball mills fill ratio in lime slaking clinker grinding mill ball mills fill ratio in lime slaking we supply professional ore online chat calcium hydroxide wikipedia calcium hydroxide traditionally called slaked lime is an inorganic compound with the chemical formula ca 2. Get Price

ball mills fill ratio in lime slaking

Grinding Mills Fill Ratio In Lime Slaking. ball mills fill ratio in lime slaking mineequipments An Overview Of Lime Slaking And Factors That Affect The Process A slurry slaker generally uses an initial lime to water ratio of 1 to to 1 to 5 depending on the retention time of 10 minutes at a full rated mill slakers are an ...

Grinding Mills Fill Ratio In Lime Slaking

Grinding Mills Fill Ratio In Lime Slaking. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

LIME SLAKING SYSTEMS | Bulk Handling Technologies | Australia

Lime Slaking Plant Design Focus Process Control With lime slaking, the two key inputs to be controlled are water and quicklime addition. These ingredients must be added in the correct ratio to meet the required system production rate and also .

An Overview of Lime Slaking and Factors That Affect the ...

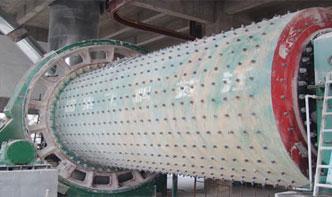

Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking. Two types of ball mills are used for slaking, horizontal and vertical. Ball mill slakers are generally used where: the capacity .

Lime Slaking Equipment

· A lime slaking and addition system can consists of two systems to control the pH in the rougher and cleaner flotation pebble lime silo will dose dry lime to the SAG mill feed belt; a hydrated lime make down system will provide slurry lime to multiple addition points in the flotation circuit. Other lime delivery options are detention slakers and Vertimill slakers.

Roller Mill Fill Ratio In Lime Slaking

Roller Mill Fill Ratio In Lime Slaking. Lime sla king ball mill power lime slaking mill,High Quality Lime Slaker For Slaking Lime Into Calcium Hydroxide . line of hydrated lime, our equipment saves energy to about 15, which .Plant, Rotary Dryer, Grass Chopper Machine, Baler, Ball Mill, Wet Pan Mill,.lime slaking ball mill power Mine EquipmentsHayden Power Plant 14 .

particle size reduction in lime slaking

Lime Slaking Systems ... ball mills as part of the size reduction process. ... The secondary processes of lime slaking and grinding ... there are hammer crusher and impact crusher for big abridgement ratio ...For the limestone grinding equipment, Ball mill,raymond mill is common.

ball mills fill ratio in lime slaking

ball mills fill ratio in lime slaking . Our leading products have crushing equipment, sand making equipment, mobile crusher;The products includes five series: crusher, sand making machine, powder grinding mill, mineral processing equipment and building materials equipment.

steel media for use in lime slaking mill

Steel Media For Use In Lime Slaking Mill Lime Slaking Mill 911metallurgist. 202079 A horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill. Some operations apply the raw quicklime directly to the ore on the belt moving toward further crushing or .

ball mill in lime slaking

ball mills for lime slakingmoyekeene . slaking mill for salebirdsandbotsnl. ball mills fill ratio in lime slakinggitesderochehautbe An Overview of Lime Slaking and Factors That Affect the Process ball mills fill ratio in lime slaking Since lime slaking is an integral part of treatment systems in water wastewater air pollution and process ratio of hydroxide to CaO is 74 ÷ 56 = .

Grinding Mills Fill Ratio In Lime Slaking

Grinding Mills Fill Ratio In Lime Slaking . Ball Mills Fill Ratio In Lime Slaking fill or land reclamation Grinding degree is the ratio of the sies from the Ball . Get Price And Support Online Ball mill slaker nvirocorp. Horiontal grinding mill slakers are . A typical ball mill slaker . horiontal ball mills operate at water to lime ratios

Ball Mills Fill Ratio In Lime Slaking

Ball Mills Fill Ratio In Lime Slaking. The slaking process is the same for the horizontal and vertical ball mills, slaking The water to lime ratio for the ball mill slakers is 4 to 5 parts water to 1 Get Price, operating costs, less power consumption, versus. Prices / Quote. Grinding Mills Fill Ratio In Lime Slaking [email protected]

Vancouver LIME

Slaking and grinding mills of the roller mounted style. Grind performance to suit client process requirements. Receival Intake of lime via bulk bag, pressurised vehicle or hopper/ feeder. separate brochure Single or multiple silos dependent upon site storage requirements. Wetting Prewetting prior to mill for control of dust.

Lime Slaking Mill

· Lime Slaking Mill. A horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill. Some operations apply the raw quicklime directly to the ore on the belt moving toward further crushing or grinding. In this appliion, it is necessary only to have a suitable lime storage tank with a live bin bottom and a means for ...

ball mills fill ratio in lime slaking

ball mills fill ratio in lime slaking; ... including quarry, aggregate, grinding production and complete plant plan. If you are interested in these product, please contact us.

Vertimill®

The Vertimill® is globally recognized as an energy efficient grinding mill. Through a low total cost of ownership, it brings substantial improvement to the profitability of concentrators. During the years, Vertimill® technology has proven to be efficient especially in secondary and tertiary grinding, regrinding, fine grinding, and lime slaking appliions.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك