iron ore treatment process

ترك تعليقك

Rcovery of gold in pyritic ores

Using cyanide to recover gold from sulfide ores generally results in 30 to 35% recovery, and the best I have heard of is around 50% recovery. The fine coating of a iron compound definitely appears to be a key component of the inability of cyanide to efficiently leach low grade pyritic ores. Perhaps there is some room here for a pretreatment, to ...

What is the Process of Metallurgy

03/12/2020 · What is the Process of Metallurgy The various steps used in metallurgy are listed below. 1. Enrichment or dressing of the ore 2. Conversion of the enriched ore into the oxide of metal 3. Extraction of metal from the metal oxide 4. Refining or purifiion of the metal Enrichment or dressing of an ore : [.]

Upgrading LowGrade Iron Ore through Gangue Removal by a ...

In this study, a combination of alkali roasting and hydrothermal treatment is used as a method of gangue (Si, Al, and P) removal from iron ores as a means to upgrade lowgrade iron ore (limonite) into a highgrade iron ore with low gangue content, low porosity, and high Fe and Fe 2 O 3 content to enhance the sustainable development of iron and steel industries.

Operations – Karara Mining

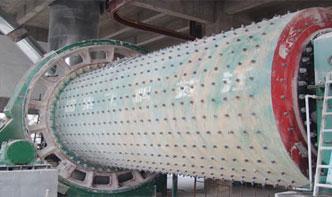

Karara comprises a largescale, longlife magnetite orebody amenable to bulk mining and processing. Magnetite ore has lower iron content (3436% Fe) than hematite ore (5864% Fe). It must be upgraded by a complex ore treatment process (beneficiation) to produce a highgrade (+65% Fe) concentrate for steelmaking.

Direct reduced iron process

21/06/2018 · Direct reduced iron (DRI) process. In addition to the process route via the blast furnace process, there is another option for extracting crude steel from iron ores using the socalled direct reduced iron (DRI) process (secondary route).The starting point for the efforts to find an alternative to the blast furnace process was the relatively high process expenditure.

Iron Ore Benefeion Process

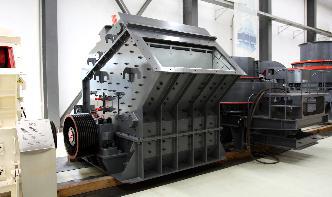

This ore processing will be discussed in detail in the next section. Iron ore processing. After the iron ore has been prepared by crushing and grinding during ore extraction, the ore is actually 03, 2014 The process adopted to upgrade the Fe content of iron ore is known as iron ore beneficiation (IOB).

Iron Removal: A World Without Rules

When used in iron removal, the softener uses a ion resin to exchange iron for sodium, in addition to the calcium and magnesium exchanged for sodium in the softening process. Softeners are commonly used in removing low levels of ferrous iron (13 ppm), though it is not uncommon to remove 10 or more ppm depending on water conditions and ...

(PDF) Mineral Processing Technology An Introduction to the ...

Mineral Processing Technology mineria procesamiento de minerales. Mineral Processing Technology An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, by Barry A. Wills, Tim NapierMunn

Iron Mining In Minnesota 1800s1900s

The ore itself was found in Minnesota by a geologist in 1865. They didn't realize the true wealth and vastness of the iron ore until the 1890s. They used iron ore for various reasons. Such as making parts for trains, railroads, and buildings. Trains would deliver the ore to oreloading docks in Duluth, Superior, Two Harbors, and Wisconsin.

Metals | Free FullText | Hydrogen Ironmaking: How It ...

03/06/2020 · A new route for making steel from iron ore based on the use of hydrogen to reduce iron oxides is presented, detailed and analyzed. The main advantage of this steelmaking route is the dramatic reduction (90% off) in CO2 emissions compared to those of the current standard blastfurnace route. The first process of the route is the production of hydrogen by water .

Metallurgical Testing for Iron Ore

For the iron ore exploration and mining industries, SGS Minerals Services provides a comprehensive range of metallurgical testwork services. Our extensive global network of laboratory and metallurgical testing facilities support most of the processes that are used in the exploration and treatment of iron ore. At the broadest level, these include:

Phosphorus Removal from Goethitic Iron Ore with a Low ...

processes do not remove sufficient phosphorus from the ores to meet market specifiions of % P. Processing to disrupt the goethite structure to make the phosphorus amenable to leaching is necessary. Phosphorus associated with the goethite in highphosphorus iron ores can be removed to % P using a heat treatment at 300–350°C for 1 ...

Blast Furnace: Definition, Construction or Parts, Working ...

Iron ore is treated in two stages before entering the blast furnace. The twostage treatment of iron ore are. ... In this process, the ore is first crushed into small pieces and then is again crushed to form a powder. The powdered ore is then washed in a water current in which the lighter impurities are removed and the heavier ore is settled down.

thermal treatment process in iron ore green pellet

thermal treatment process in iron ore green pellet. Iron ore pellets figure are one of the main raw materials for steelmaking they are produced from ore fines in a process called pelletizing, which consists of two basic steps the first is the formation of the soft green pellet from the iron ore fines and the second step requires a heat treatmentget price

Improvement of the Control Process of the Heat Treatment ...

02/03/2021 · The object of research is the process of heat treatment of iron ore pellets. To study it, a technological zone of preheating of a conveyortype roasting machine was used. Technological process control is performed on the basis of fuzzy and incomplete information about the state of this zone.

How Steel is Made Using the Basic Oxygen Steelmaking Process

IronOre Ironore are rocks and minerals that contain the metal iron (Iron Ore). Ironore is harvested in largescales through various mining techniques (STEEL: From Start to Finish). The ironore is ground to a powder and then the ore is separated with strong magnets (STEEL: From Start to Finish). The ore is then heated and formed into marble ...

The Steel Making Industry

One such procedure is the Japanese Direct Iron Ore Smelting (DIOS) process (Figure 2). The DIOS process produces molten iron from coal and previously melted ores. In this process, coal and other ores can produce enough heat to melt ore, replacing coke completely (USEPA, 1995).

Timeline of metal processes, heat treatments ...

Interactive timeline of metal processes, heat treatments, surface technology Bodycote ... One site in particular in the Ferghana Valley showed evidence of carburised iron ore; this process appeared to be restricted to this particular area and so was named the Ferghana process. ... Carburising is a heat treatment of iron or steel causing it to ...

Chapter 6 Copper Production Technology

Copper ores Copper ore, other minerals, waste (gangue) Copper minerals,b iron and other pyrites, byproducts, andgangue Solution of copper and leaching agent2050 (water orHAO.) Copper, iron (/0), trace amounts of8590 silica and aluminum oxides, and oxygen Organic solvent and pregnantIeachate; 2535

(PDF) Beneficiation techniques for Iron ores from Eastern ...

Relevance of geological aspects and ore mineralogy in selecting beneficiation methods for processing of eastern Indian iron ores R. K. Upadhyay*1, S. Roy2, A. S. Venkatesh2, M. V. S. Rao1 and P. K. Banerjee1 Geological aspects, particularly mineralogy and ore genesis of different iron ores have important roles to play in understanding their behaviour during processing .

Iron and Steel Manufacturing

Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufacturing process or a direct reduction process. In the conventional integrated steel manufacturing process, the iron from the blast furnace is converted to steel in a basic oxygen furnace ...

Iron Ore Treatment Process

Iron Ore Treatment Process Meine Sternapotheke. Process of making iron from oreiron ore is an important raw material for iron and steel production sintering process of iron ore fines ispatguru3/9/2013 · the process of sintering is basically a pretreatment process step during iron making for the production of the charge material called sinter for the blast furnace .

Electrowinning of Iron in Aqueous Alkaline Solution Using ...

10/12/2008 · The regenerated was used to treat iron sulfide ores to produce sulfur and 6, 7 The Pyror process shown in Fig. 1d was based on the electrowinning of iron from an aqueous solution, which was generated by treating iron sulfide ore by using sulfuric acid.

لمعرفة كيف يمكن أن خبرتنا ومعرفة الصناعة تساعدك على تحقيق أهدافك، اتصل موظفينا على دراية على الانترنت. أيا كان مستوى المشاركة المطلوبة، من مجرد تقديم المشورة لتوفير حل كامل جاهز، ونحن ملتزمون تجاوز احتياجاتك.

جون فرانك